Get Better Quality and More Consistency with the INTEGRA P 450

April 13, 2022 | Reading time: 3 min

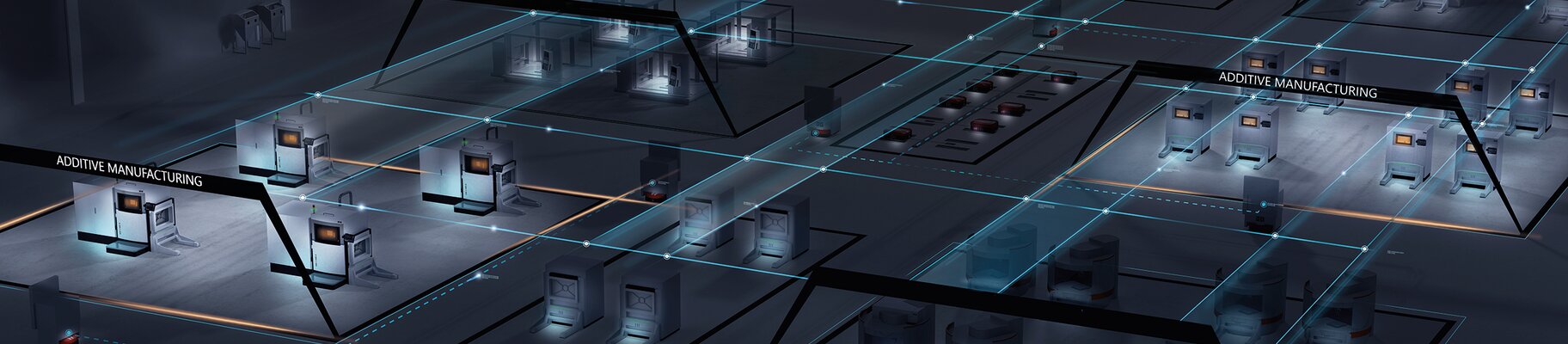

Real and virtual learning worlds will be the cornerstone of the additive manufacturing industry. Additive Minds Academy bundles all competencies relating to training, learning and knowledge sharing.

To really leverage additive manufacturing (AM), companies need advanced solutions that provide excellent part quality and consistency. With 8-Zone quartz heating and a thermal imaging camera, the INTEGRA P 450 ensures consistent and fast heating over the entire build platform, which is a key element for achieving highly repeatable part quality.

8-Zone Quartz Heating

Additive manufacturing has the potential to radically transform the production of industrial goods, but until recently, repeatability has been a barrier to more widespread adoption. When comparing different AM technologies, surface and functional properties of parts can fluctuate dramatically. Quality variations can also occur at different spots within a specific machine’s build area, and sometimes inconsistently from run-to-run.

Nesting refers to the process used to arrange 3D objects within the build area of a specific AM device. Depending on the quantities needed, a build platform can be filled with multiple copies of the same design, or it can include many different parts. Not only does nesting ensure parts are produced in the correct orientation, it also helps optimize packing density and reduce waste. But, if the heat source isn’t consistent, variations can occur from part-to-part and job-to-job.

With its recent introduction of the INTEGRA P 450, EOS North America is setting a new standard for part quality and repeatability. To ensure fast and consistent heating, the INTEGRA P 450 features an exclusive 8-zone quartz heating system. Each zone is independently adjustable, allowing operators to achieve an even thermal distribution over the entire build platform, which is a key ingredient to achieving predictably high quality.

Thermal Imaging Camera

Leading-edge companies know that digital transformation can help them gain productivity and improve their manufacturing operations. Many are investing in industrial Internet of Things (IoT) initiatives, with the goals of enhancing visibility, improving quality, and reducing cost. Research from ITIF for example, predicts that IoT applications in manufacturing and factory settings will generate $1.2 to $3.7 trillion of economic value by 2025 and that applications for machine monitoring alone could increase manufacturing productivity by 10 to 25%.

Additive manufacturing by itself is transformative, but the value multiplies when AM is integrated with other emerging technologies. With the launch of the INTEGRA P 450, EOS North America is setting new standards for machine monitoring. The system’s onboard thermal imaging camera provides real-time measurement and data-capture of temperature throughout the part bed enabling accuracy, repeatability, and process quality control.

A Powerful Combination

Working together, the P 450’s thermal imaging camera and 8-zone quartz heating capabilities help companies produce high quality parts more consistently. Using infrared (IR) sensors, the camera provides precise indication of hot and cold spots in the part bed, while a live display and 8-zone quartz heating give operators real-time insight and flexibility to balance each zone independently.

Artificial intelligence (AI) and machine learning may also play a future role. As the INTEGRA P 450’s software continues to evolve, it could incorporate AI to improve closed-loop feedback and provide automatic thermal balancing. Together these tools would help customers improve communication on the factory floor, while also helping them further automate their workflows.

Conclusions

Manufacturers understand the benefits of digital transformation and expect their suppliers and business partners to support their initiatives. Additive manufacturing can play a central role, but part quality must be consistently accurate. EOS helps AM deliver on its potential by incorporating advanced tools, including 8-zone quartz heating and a thermal imaging camera, that enable the INTEGRA P 450 to diagnose and remedy temperature-related issues, ultimately resulting in superior part quality from part-to-part and run-to-run.

Author: Cary Baur