Get Inspired: Metal Additive Manufacturing Solutions

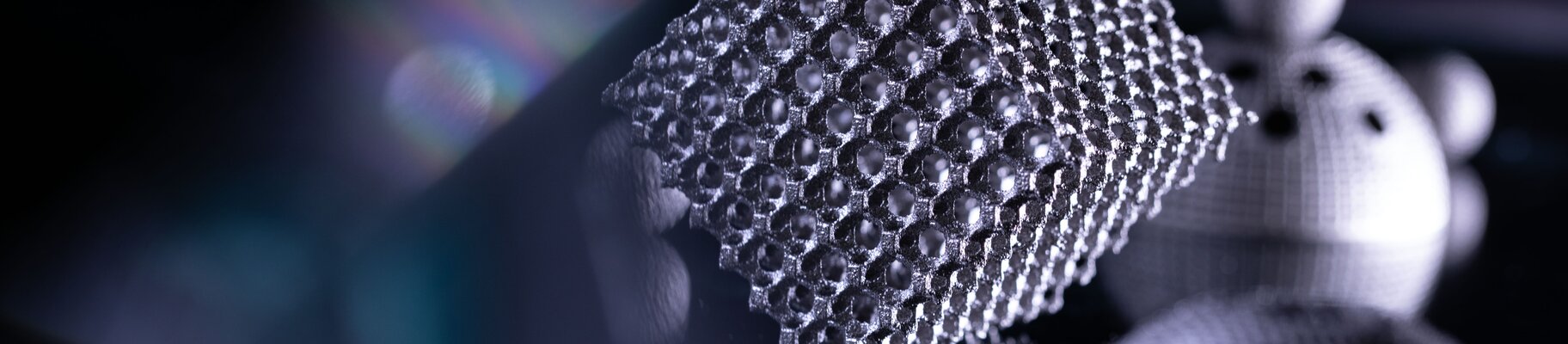

Metal Additive Manufacturing Solutions

Industrial quality parts – every single time

Our industrial metal 3D printing solutions allow for highly reproducible industrial-grade parts, no matter how intricate your design or how daring your plans are to scale. EOS offers unparalleled flexibility, so you can easily adapt your manufacturing and application design to fit your production and customization needs.

Our metal 3D printing customers include a vast collection of organizations, including market leaders, industry disruptors, and national research labs. From aerospace and automotive, to medical implant manufacturers, to renewable energy and consumer goods, we have provided metal industrial 3D printing solutions that fit each one’s needs. Explore a few of our customer success stories and get inspired for your next 3D printed application project.

Rocket Engine with LAUNCHER

When leveraging 3D printing for rocket engine manufacturing, the functionality of components can be completely reimagined and reinvented. For example, you can integrate cooling channels into a combustion chamber, or consolidate multiple parts into a singular design. Supported by EOS and AMCM, the U.S. aerospace company VAST is launching small to medium-sized payloads into space more efficiently than ever before. The results include novel and innovative rocket designs – and the world’s largest rocket engine to ever be manufactured additively in a single piece. The engine is based on a standard rocket design but is extended with internal ribs for optimal cooling. VAST successfully constructed, tested and further developed this new design quickly and cost-efficiently, entirely thanks to 3D printing. When beginning the project, the build space and material properties were quickly identified as obstacles. AMCM, a company in the EOS group that offers specialized machines tailored to customer requirements, accepted this challenge.

The combustion chamber, 3D printed from a copper alloy on AMCM’s M4K machines, is the largest single-piece combustion chamber for liquid rocket engines in the world. The chamber is 86 cm (34 in) high, with an outlet nozzle diameter of 41 cm (16 in). The booster has won a $1.5 million prize at the US Air Force Space Pitch Day, which was held to accelerate the development and testing program of the E-2 booster. The first large-scale test runs have already been planned.

“Traditionally, manufacturing this type of part requires millions of dollars of investment in custom machines. Now, with 3D printing there is the option to print the combustion chamber, nozzle and neck combined into a single piece. Thanks to this progress, our work is easier than ever before.” – Max Haot, Chief Executive Officer of VAST

Future Ariane Propulsion Module Simplified

„Mission Critical“ perfectly describes the Class 1 components used in the aerospace industry. Missions costing hundreds of millions depend on these components. Accordingly, engineers are constantly seeking to develop components of the highest quality, functionality, and robustness while simplifying the manufacturing chain and reducing the number of individual elements. Thanks to EOS additive manufacturing technology, ArianeGroup has succeeded in taking this to a whole new level: Instead of 248 elements, the injector head of a rocket engine of a future upper stage propulsion module now counts just one component. The injector head has been simplified and reduced to what is literally an all-in-one (AiO) design.

"On Ariane program, we are combining our innovative strength with the expertise of EOS. Together, we work on the additive manufacturing of an injector head for a rocket engine. The results are impressive: Significant reduction in production time and 50 % lower costs." – Dr.-Ing. Steffen Beyer, Head of Production Technology, Materials & Processes of ArianeGroup

3D Printing an Antenna Satellite Bracket with RUAG

For many people, talking of the infinite vastness of the universe conjures up stories of science fiction, usually told by a Hollywood film studio. However, in real life, more than in any other area, it is arguably in space travel that a strong will and clear vision are vital for creating the necessary technology and readying it for deployment in the cosmos. This was the challenge faced by Swiss technology group RUAG in the construction of its Sentinel satellite, designed for observing our planet from on high. Even here, beyond the Earth's atmosphere, AM is playing a key role. Swiss RUAG group needed an optimally designed antenna bracket, with weight optimization being a crucial element, but not the only aspect that needed to hold up in the comparison of AM vs. traditional manufacturing. Because of the vibrations and G-forces that a part is subjected to during a rocket launch and orbit, stability and rigidity formed a second essential element to the redesign.

“EOS combines innovation with great experience in additive manufacturing. The systems offer really interesting possibilities for all markets across every sector.” – Andreas Berkau, CEO, CITIM GmbH

Discover More

Metal Success and Blog Stories Enabled by EOS

Selection of Material

Metal Webinars & Whitepaper Enabled by EOS