Quality Assurance in 3D Printing

EOS Standards and Certifications

Many sectors, including the aerospace, automotive and medical industries, require carefully tested and consistent part quality. How can this be achieved with additive manufacturing? Find out how EOS has established a quality management system that is unrivaled.

We continuously control the quality of every part at every process step in the value chain and have obtained product certifications and validations to prove this. The objective of our quality policy is to identify current customer needs and recognize future market requirements at an early stage so we can meet them with appropriate organization, technical and economic means.

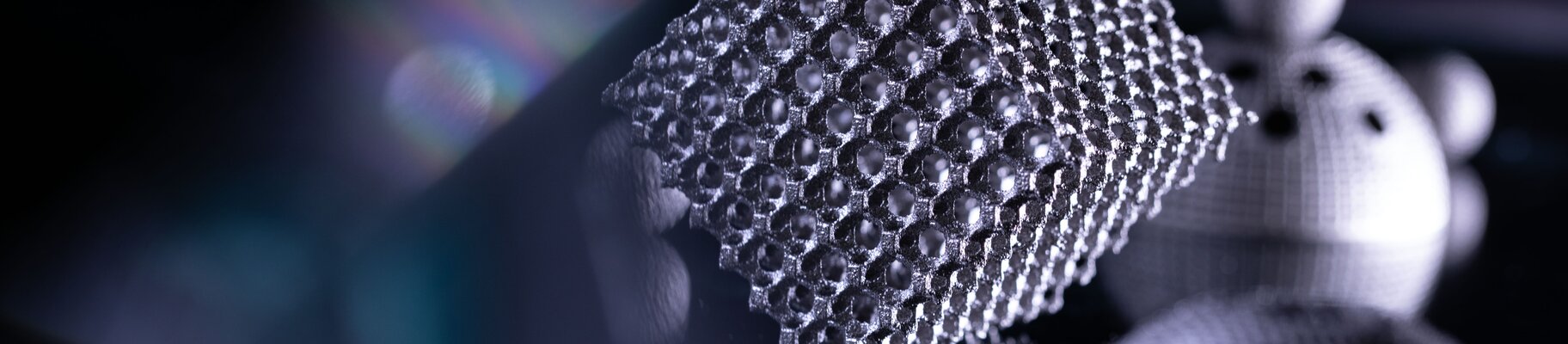

Industrial 3D Printing Quality Assurance Approach For System, Material, and Process

Our joint development and multilateral coordination between the three elements (system, material and process) draw from 30 years of experience. In this way, we create the conditions for uniform, repeatable and reliable part properties. The result? Unsurpassed part quality. With comprehensive quality assurance measures in all three areas, EOS has established an integrated quality approach for series production.

Whitepaper "Hands-on Quality"

In many industries, such as aerospace and medical technology, there are strict requirements for the qualification and certification of parts, materials and processes. Which quality requirements can EOS additive manufacturing meet?

Our whitepaper describes the quality assurance processes and standards fulfilled by EOS systems, processes and materials.

You will find answers to the following questions:

- What are the decisive factors of quality in additive manufacturing?

- How does EOS conduct quality assurance in product and process development?

- What are examples of useful standards in quality assurance?