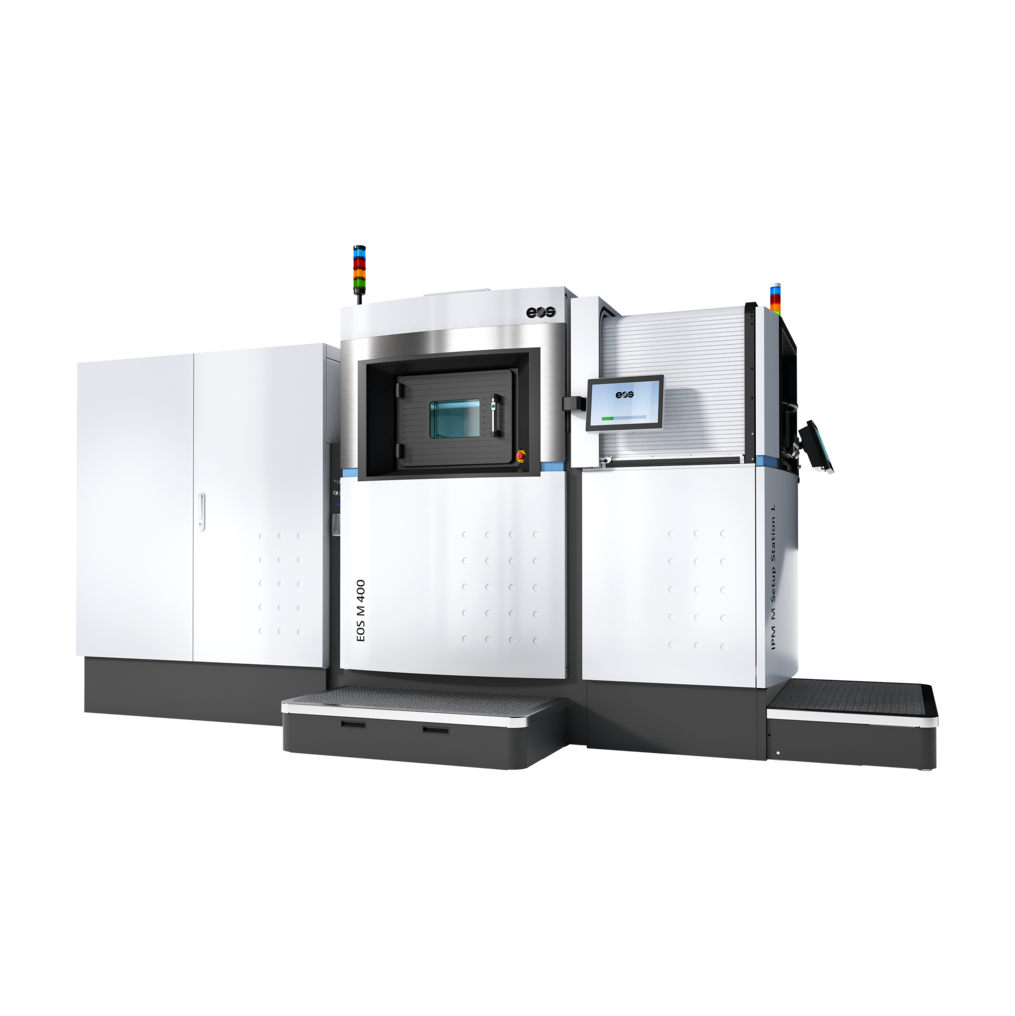

Exceptional Quality at High Volume

Ideal for serial manufacturing of large metal parts, the EOS M 400 delivers repeatable excellence.

Technical Data

EOS

M 400

| Build Volume | 400 x 400 x 400 mm (15.7 x 15.7 x 15.7 in) |

| Laser Type | Yb-fiber laser; 1 x 1000 W |

| Presicion Optics | 1 F-theta-lens(es); 1 High-speed scanner(s) |

| Scan Speed | up to 7.0 m/s (23.0 ft/s) |

| Focus Diameter | approx. 90 µm (0.00354 in) |

| Power Supply | 1 x 50 A |

| Power Consumption | max. 50.2 kW / typical 16.2 kW |

| Compressed Air Supply | 7 Bar; 20 m³/h (102 psi; 706 ft³/h) |

| Machine Dimensions | 4181 x 1613 x 2355 mm (164.6 x 63.5 x 92.7 in) |

| Recommended Installation Space | min. 6500 x 6000 x 3300 mm (255.9 x 236.2 x 129.9 in) |

| Weight | approx. 4635 kg (10218 lbs) |

| Software | EOS BUILD , EOS SYSTEM SUITE |

Materials & Processes for EOS M 400

A broad portfolio of materials is available for EOS M 400 - from light metals to stainless steel, tool steels and super-alloys. Browse compatible materials and processes below.

Aluminium

Cobalt Chrome

Copper

Nickel Alloys

Stainless Steel

Titanium

Tool Steel

Get Inspired

Expand Your AM Knowledge & Skills

Software Solutions that Scale to Your Needs

EOS Technical Service

From getting started to sustainable success

We always focus on your success. From a certified start in the 3D printing process to qualified system maintenance and globally available support with a convenient service portal which provides you with information around your machine and service tickets 24/7.

You’ll find the right service package among the various technical services we offer. Our EOS SystemCare Program is tailored to your specific requirements.