- All 3D printed parts with excellent mechanical properties and dimensional accuracy due to software features such as Smart Scaling, EOSAME and a continuous temperature monitoring.

- Highest productivity ensured by its powerful laser plus high scanning and recoating speed.

- A multitude of applications that fully meet industry requirements is possible with the 14 materials and their 26 parameter sets.

- Full integration into the IIoT environment with EOSCONNECT Core resulting in an entirely digital process chain from the CAD model, through ERP and MES connection, to the finished part.

- Maximum machine park uptime with digital track and trace from everywhere and at any time.

- Continuous optimization of the entire production workflow made possible with the evaluation and documentation of all build cycles.

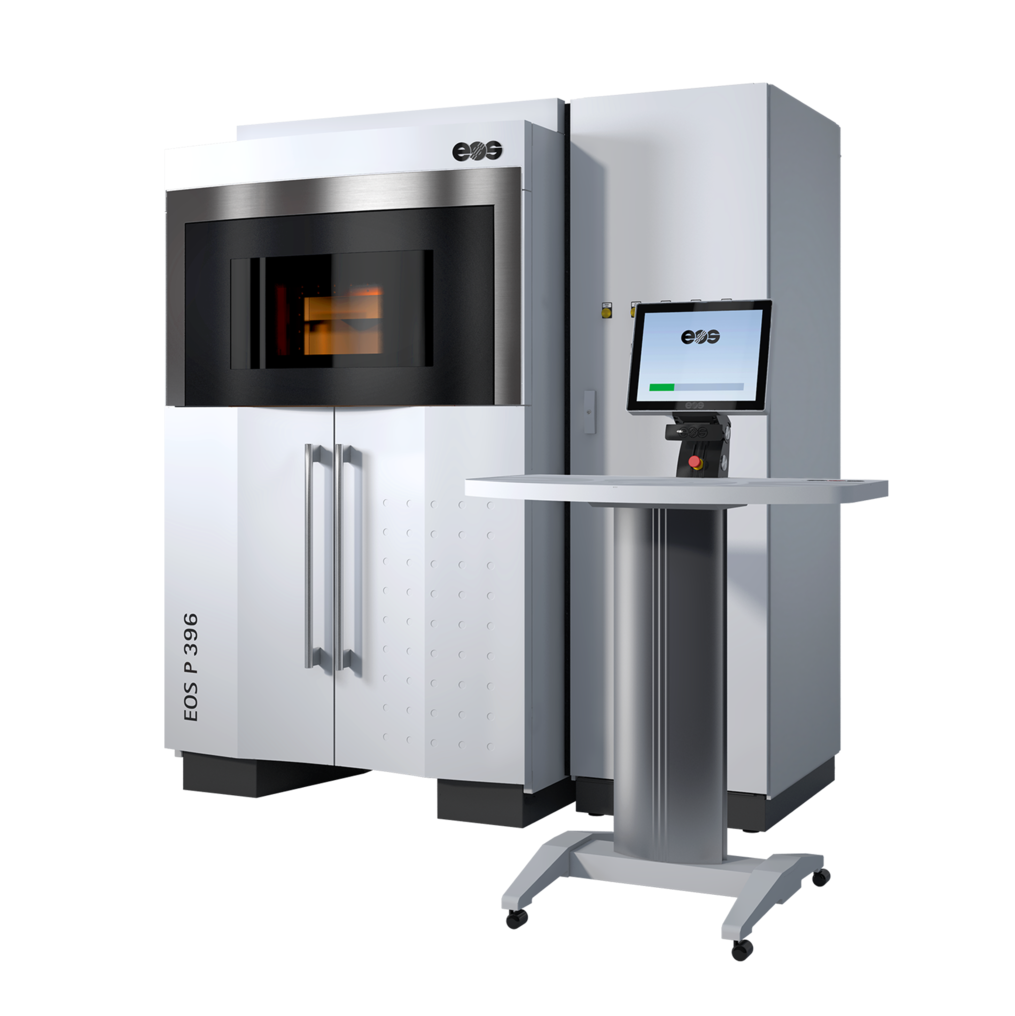

EOS P 396

Reliable Production with the Industry‘s Largest Material Portfolio

The medium-sized bestselling EOS P 396 can be integrated into IIoT environments. It enables a flexible and tool-free production of everything from spare parts on-demand, to serial production.

EXPOSURE MODULE

- 1 x

70 W

SOFTWARE

-

EOS SYSTEM SUITE EOS System Suite optimizes production by streamlining processes, integrating with MES and shop-floor IT systems, and generating detailed quality reports.

EOS P 396

TECHNICAL DATA

| BUILD VOLUME | 340 x 340 x 600 mm (13.4 x 13.4 x 23.6 in) |

| LASER TYPE | CO₂; 1 x 70 W |

| SCAN SPEED | up to 6.0 m/s (19.7 ft/s) |

| POWER SUPPLY | 1 x 32 A |

| POWER CONSUMPTION | max. 10.0 kW / typical 2.1 kW |

MATERIALS & PROCESSES

EOS P 396

-

PA 1100

-

PA 1101

-

PA 1101 ClimateNeutral

-

PA 1102 Black

-

PA 2200 Balance

-

PA 2200 CarbonReduced Balance

-

PA 2200 Performance

-

PA 2200 CarbonReduced Performance

-

PA 2200 Speed

-

PA 2200 CarbonReduced Speed

-

PA 2200 Top Quality

-

PA 2200 CarbonReduced Top Quality

-

PA 2200 Top Speed

-

PA 2200 CarbonReduced Top Speed

-

PA 2201

-

PA 3200 GF

-

Alumide

-

EOS TPU 1301

-

PA 2210 FR

-

PA 2241 FR

-

FR-106

-

HP 11-30

-

PA 640 GSL