EOS NickelAlloy K500

Material Data Sheet

EOS NickelAlloy K500

Versatile alloy for highly corrosive environments

EOS NickelAlloy K500 is a versatile alloy designed for especially highly corrosive environments. The material offers a unique combination of mechanical properties, corrosion resistance, and thermal conductivity that make it ideal for a variety of demanding applications.

- Good mechanical strength also in elevated temperatures

- Excellent corrosion resistance

- Moderate conductivity (approximately two times the conductivity of commonly used nickel superalloys)

- Aerospace

- Marine

- Industrial applications

The EOS Quality Triangle

EOS incorporates these TRLs into the following two categories:

- Premium products (TRL 7-9): offer highly validated data, proven capability and reproducible part properties.

- Core products (TRL 3 and 5): enable early customer access to newest technology still under development and are therefore less mature with less data.

All of the data stated in this material data sheet is produced according to EOS Quality Management System and international standards

POWDER PROPERTIES

Powder and built part compositions of the EOS NickelAlloy K500 conform to the chemical composition requirements of UNS N05500.

Powder Chemical Composition (wt.-%)

| Element | Min. | Max. |

|---|---|---|

| Ni | 63.0 | - |

| Cu | 27.0 | 33.0 |

| Al | 2.3 | 3.15 |

| Fe | - | 2.0 |

| Mn | - | 1.5 |

| Ti | 0.35 | 0.85 |

| Si | - | 0.5 |

| C | - | 0.25 |

| S | - | 0.01 |

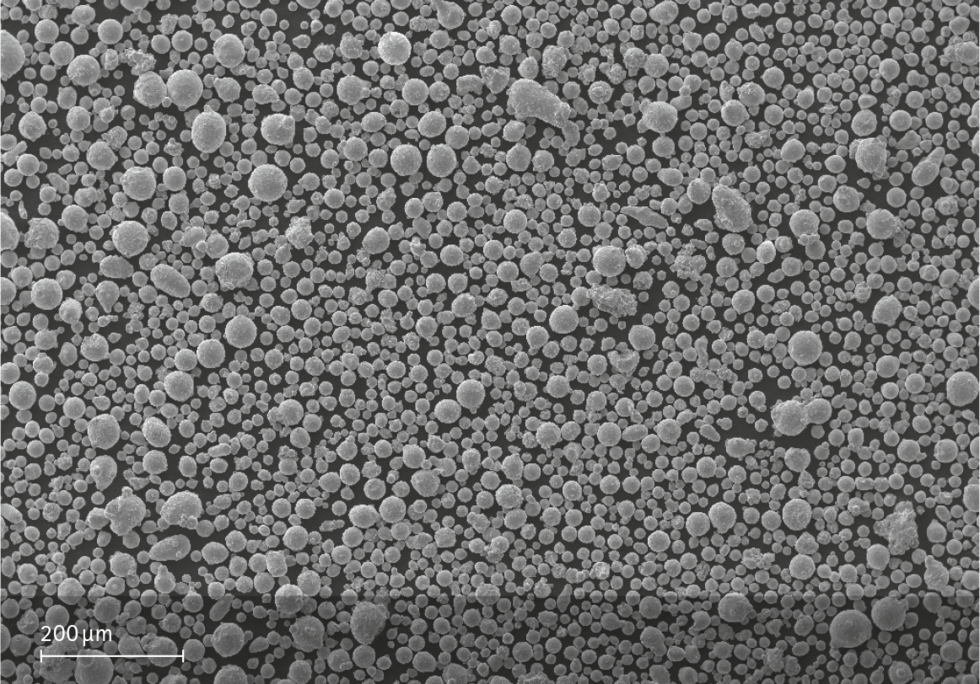

Powder Particle Size

| GENERIC PARTICLE SIZE DISTRIBUTION | 15 - 75 μm | |

|---|---|---|

SEM micrograph of EOS NickelAlloy K500 powder

HEAT TREATMENT

EOS NickelAlloy K500 is a precipitation strengthened alloy. The strength of the material can be tailored using heat treatment. An ageing heat treatment directly after printing is recommended for applications where strength is the primary concern.

Direct aging

Hold at 595 °C measured from the part for 2 h in argon atmosphere, followed by slow air cooling.