METAL SOLUTIONS

EOS Nickel NiCP

Material Data Sheet

EOS Nickel NiCP

Commercially Pure Nickel

Ideal for semiconductor and chemical applications requiring Nickel purity, corrosion resistance and ductility. This material provides a tensile strength of 400 MPa and 49% elongation, making it an ideal candidate for applications like gas injectors and corrosion resistant components within semiconductor capital equipment.

- High purity

- High ductility

- Good corrosion resistance

- Semiconductor manufacturing parts

- Chemical industry parts

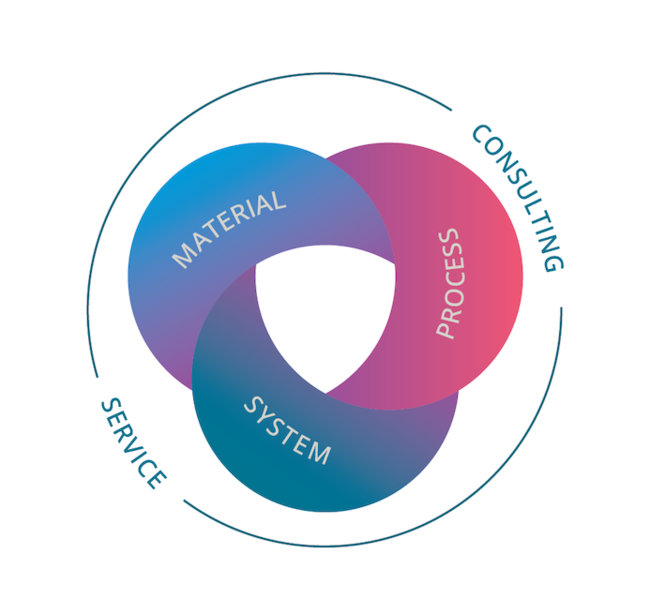

The EOS Quality Triangle

EOS uses an approach that is unique in the AM industry, taking each of the three central technical elements of the production process into account: the system, the material and the process. The data resulting from each combination is assigned a Technology Readiness Level (TRL) which makes the expected performance and production capability of the solution transparent.

EOS incorporates these TRLs into the following two categories:

All of the data stated in this material data sheet is produced according to EOS Quality Management System and international standards

EOS incorporates these TRLs into the following two categories:

- Premium products (TRL 7-9): offer highly validated data, proven capability and reproducible part properties.

- Core products (TRL 3 and 5): enable early customer access to newest technology still under development and are therefore less mature with less data.

All of the data stated in this material data sheet is produced according to EOS Quality Management System and international standards

POWDER PROPERTIES

Powder and built part compositions meet the chemical composition requirements of ASTM B162 and SAE AMS5553.

Powder Chemical Composition (wt.-%)

| Element | Min. | Max. |

|---|---|---|

| Ni | 99 | - |

| C | - | 0.02 |

| Mn | - | 0.35 |

| Si | - | 0.35 |

| S | - | 0.01 |

| Fe | - | 0.4 |

| Cu | - | 0.25 |

Powder Particle Size

| GENERIC PARTICLE SIZE DISTRIBUTION | 15 - 63 μm | |

|---|---|---|

SEM micrograph of EOS Nickel NiCP powder

HEAT TREATMENT

Heat treatment procedure

Step 1:

Stress relieve: Hold temperature 580 °C, hold time minimum 2 h when thoroughly heated. Air cooling or equivalent cooling rate.