EOS Aluminium Al2139 AM

Material Data Sheet

EOS Aluminium Al2139 AM

Highest Strength Aluminium Alloy in AM

EOS Aluminium Al2139 AM is a 2000-series high strength alloy specifically designed for AM. It demonstrates outstanding performance in elevated temperatures up to 200°C. Excellent strength properties include yield and tensile strength around 500 MPa in heat treated state and allow lightweight part design. The fast and simple heat treatment procedure enables an affordable part production.

- Unmatched strength in temperatures between 50-200 °C

- Robust one-step heat treatment

- Parts can be electropolished and anodized

- Aerospace

- Racing

- Transportation & Mobility

- Lightweight designs

The EOS Quality Triangle

EOS incorporates these TRLs into the following two categories:

- Premium products (TRL 7-9): offer highly validated data, proven capability and reproducible part properties.

- Core products (TRL 3 and 5): enable early customer access to newest technology still under development and are therefore less mature with less data.

All of the data stated in this material data sheet is produced according to EOS Quality Management System and international standards

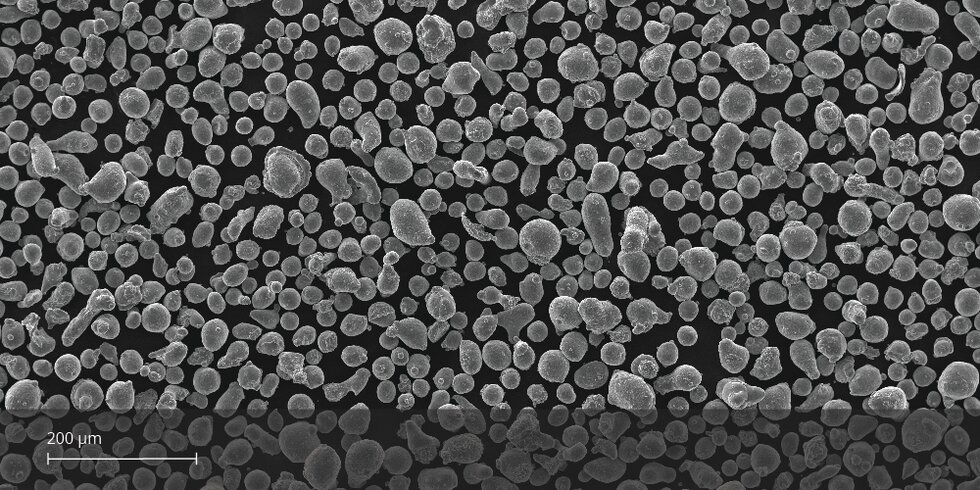

POWDER PROPERTIES

The chemical composition of the EOS Aluminium Al2139 AM powder is modified from Aluminium Association Teal Sheet for Al2139 (wrought aluminium alloys).

Powder Chemical Composition (wt.-%)

| Element | Min. | Max. |

|---|---|---|

| Al | Balance | |

| Cu | 4.5 | 5.5 |

| Mg | - | 0.8 |

| Ag | 0.15 | 0.6 |

| Mn | 0.2 | 0.6 |

| Zn | - | 0.25 |

| Si | - | 0.1 |

| Fe | - | 0.15 |

| Cr | - | 0.05 |

| V | - | 0.05 |

| Other Metallic Additions | - | 4 |

Powder Particle Size

| GENERIC PARTICLE SIZE DISTRIBUTION | 20 - 63 μm | |

|---|---|---|

SEM micrograph of EOS Aluminium Al2139 powder

HEAT TREATMENT

EOS Aluminium Al2139 AM recommended T4 Heat Treatment

Solution annealing 45 min @ 490 °C, water quench. Natural aging 3 days in room temperature.

Step 1: Solution annealing of 45 minutes in 490 °C followed by immediate quenching to water.

Step 2: Natural aging in room temperature for 3 days.

EOS Aluminium Al2139 AM for EOS M 290 | 60 µm

EOS M 290 - 60 µm

| System Setup | EOS M 290 |

|---|---|

| EOS Material set | Al2139AM_060_CoreM291_110 |

| Software Requirements |

EOSPRINT 2.7 or newer EOSYSTEM 2.11 or newer |

| Recoater Blade | HSS (High Speed Steel) |

| Nozzle | EOS Grid Nozzle |

| Inert gas | Argon |

| Sieve | 75 µm |

| Additional Information | |

|---|---|

| Layer Thickness | 60 µm |

| Volume Rate | 7.2 mm³/s |

| Wall Thickness | 0.4 mm |

Chemical and Physical Properties of Parts

The chemical properties of the parts are the same as that of the powder.

Microstructure of the Produced Parts

| Defects | Thickness | Result | Number of Samples |

|---|---|---|---|

| Average Defect Percentage | 60 µm | 0.2-0.3 % | - |

| Density EN ISO 3369 | Thickness | Result | Number of Samples |

|---|---|---|---|

| Average Density | 60 µm | ≥ 2.84 g/cm³ | - |

Mechanical Properties

Mechanical Properties Heat Treated

| EN ISO 6892-1 Room Temperature | Yield Strength [MPa] | Tensile Strength [MPa] | Elongation at Break [%] | Reduction of Area Z [%] | Number of Samples |

|---|---|---|---|---|---|

| Vertical | 460 | 520 | 4 | - | - |

| Horizontal | 460 | 540 | 6 | - | - |

Mechanical Properties

Mechanical Properties As Manufactured

| EN ISO 6892-1 Room Temperature | Yield Strength [MPa] | Tensile Strength [MPa] | Elongation at Break [%] | Reduction of Area Z [%] | Number of Samples |

|---|---|---|---|---|---|

| Vertical | 350 | 380 | 6 | - | - |

| Horizontal | 350 | 380 | 8 | - | - |

Hardness

| Heat Treated | |

|---|---|

| Value | 162 |

| Unit | HBW 2.5/62.5 |

Hardness

| As Manufactured | |

|---|---|

| Value | 112 |

| Unit | HBW 2.5/62.5 |

Stress Rupture Performance

Elevated temperature properties

EOS Aluminium Al2139 AM for EOS M 400-4 | 50 µm

EOS M 400-4 - 50 µm

Process Information Metal

High performance process with good microstructure and excellent mechanical properties and low anisotropy after heat treatment. Good mechanical properties at elevated temperatures in heat treated condition. Process offers good buildability of small features with soft recoating. Part and support design for high strength aluminium is required.

| System Setup | EOS M 400-4 |

|---|---|

| EOS Material set | Al2139AM_050_CoreM404 |

| Software Requirements |

EOSPRINT 2.10 or newer EOSYSTEM 2.14 or newer |

| Recoater Blade | HSS (High Speed Steel) |

| Build Platform Temperature | 195 °C |

| Inert gas | Argon |

| Sieve | 75 µm |

| Additional Information | |

|---|---|

| Layer Thickness | 50 µm |

| Volume Rate | up to 4 x 5.0 mm³/s |

| Wall Thickness | 0.4 mm |

Chemical and Physical Properties of Parts

The chemical properties of the parts are the same as that of the powder.

Microstructure of the Produced Parts

| Defects | Thickness | Result | Number of Samples |

|---|---|---|---|

| Average Defect Percentage | 50 µm | 0.1 % | - |

| Density EN ISO 3369 | Thickness | Result | Number of Samples |

|---|---|---|---|

| Average Density | 50 µm | ≥ 2.84 g/cm³ | - |

Mechanical Properties

Mechanical Properties Heat Treated

| EN ISO 6892-1 Room Temperature | Yield Strength [MPa] | Tensile Strength [MPa] | Elongation at Break [%] | Reduction of Area Z [%] | Number of Samples |

|---|---|---|---|---|---|

| Vertical | 450 | 530 | 6 | - | - |

| Horizontal | 460 | 550 | 7 | - | - |

Mechanical Properties

Mechanical Properties As Manufactured

| EN ISO 6892-1 Room Temperature | Yield Strength [MPa] | Tensile Strength [MPa] | Elongation at Break [%] | Reduction of Area Z [%] | Number of Samples |

|---|---|---|---|---|---|

| Vertical | 380 | 430 | 8 | - | - |

| Horizontal | 380 | 430 | 10 | - | - |

Hardness

| EN ISO 6506 Heat Treated | |

|---|---|

| Value | 168 |

| Unit | HBW 2.5/62.5 |

Hardness

| EN ISO 6506 As Manufactured | |

|---|---|

| Value | 115 |

| Unit | HBW 2.5/62.5 |

Stress Rupture Performance

datasheet.title.fatique

Lorem ipsum dolor sit amet consectetur adipiscing elit. Quisque faucibus ex sapien vitae pellentesque sem placerat. In id cursus mi pretium tellus duis convallis.

test method

Elevated temperature properties