METAL SOLUTIONS

EOS

M 290-2

- Dual 400 W lasers offer full-field overlap and quality consistent to legacy single-field system

- Increase in productivity with faster printing in the build space

- Ideal for utilization across a wide range of applications

EOS M 290-2

Dual 400 W lasers offer increased productivity for your 3D printing production, while ensuring high performance of material properties

*System available in Q4/2024

The system is equipped with two 400 W lasers that offer full-field overlap and optimized laminar gas flow. This ensures the high performance of material properties. Best-in-class process quality and material library comparable to EOS M 290.

EXPOSURE MODULE

LASERS

- 2 x

400 W

EOS M 290-2

TECHNICAL DATA

| BUILD VOLUME | 250 x 250 x 325* mm (9.8 x 9.8 x 12.8 in) |

| LASER TYPE | Yb-fiber laser; 2 x 400 W |

| PRECISION OPTICS | 2 F-theta-lens(es); 2 High-speed scanner(s) |

| SCAN SPEED | up to 7.0 m/s (23.0 ft/s) |

| FOCUS DIAMETER | approx. 85 µm (0.00335 in) |

| POWER SUPPLY | 1 x 32 A |

| POWER CONSUMPTION | max. 15.0 kW / typical 5.5 kW |

| COMPRESSED AIR SUPPLY | 7 Bar; 20 m³/h (102 psi; 706 ft³/h) |

* Building height = Full height minus the height of the building platform (ranging from 35mm to 40mm)

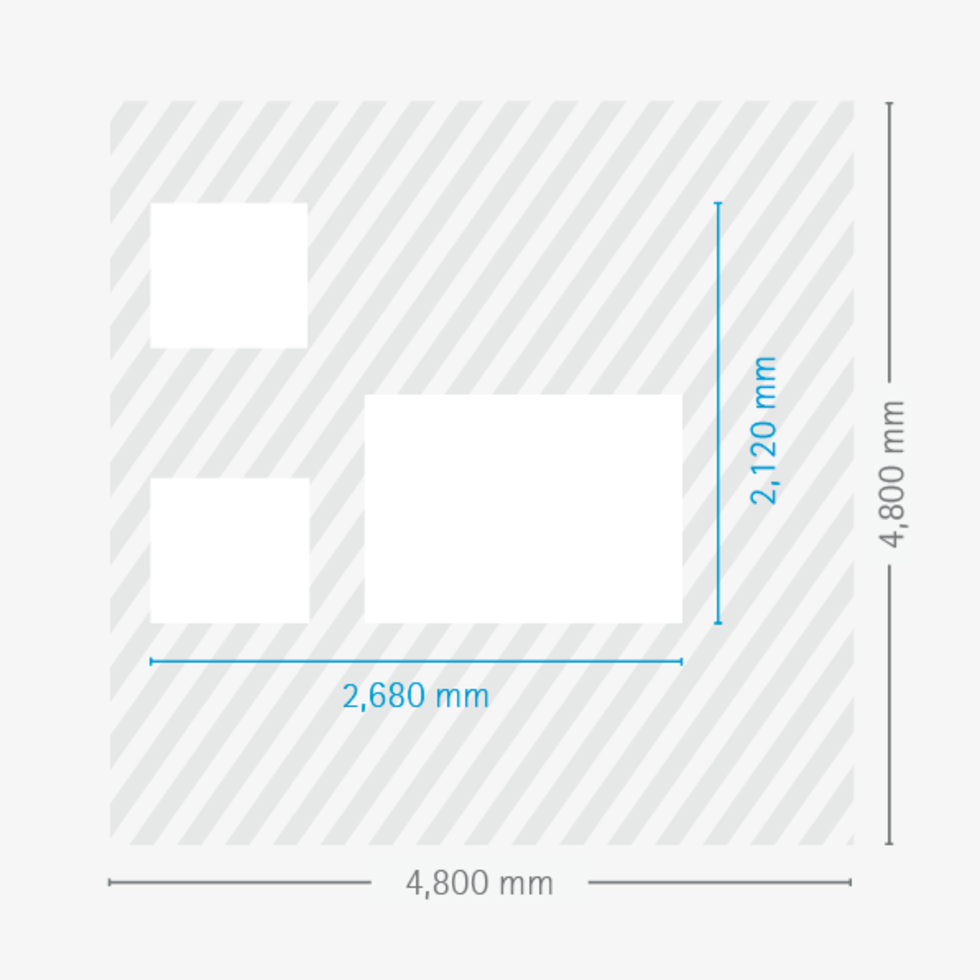

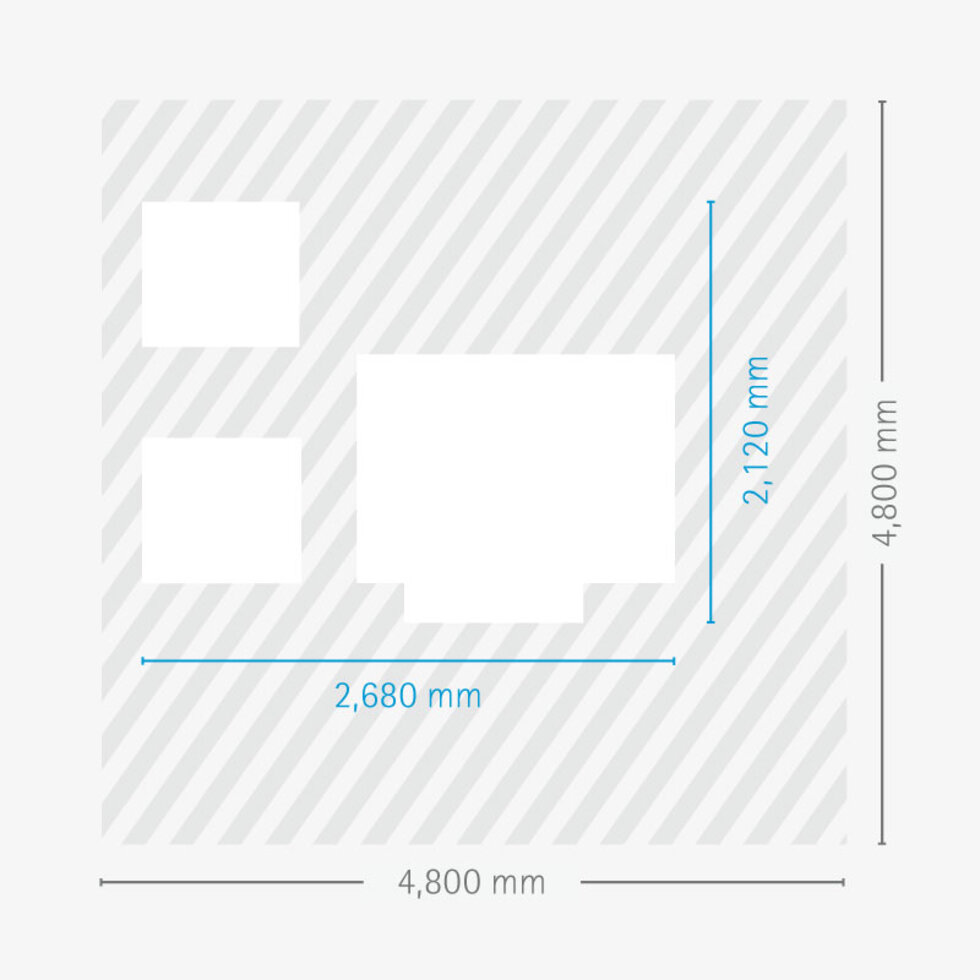

DIMENSIONS & WEIGHT

MATERIALS & PROCESSES

EOS has exceptional materials expertise and a comprehensive portfolio of highly developed materials for additive manufacturing. Our materials, systems and process parameters fit together optimally. With the right materials, you can realize the desired property profiles in the best possible way for your products

EOS M 290-2

-

EOS Aluminium AlSi10Mg

-

EOS NickelAlloy IN625

-

EOS NickelAlloy IN718

-

EOS NickelAlloy IN718 API

-

EOS StainlessSteel 17-4PH

-

EOS StainlessSteel 316L-4441

-

EOS Titanium Ti64