METAL SOLUTIONS

EOS Titanium TiCP Grade 2

Material Data Sheet

EOS Titanium TiCP Grade 2

The parts built with EOS Titanium TiCP grade 2 powder have chemical composition corresponding to ASTM F67. The parts have good strength-to-weight ratio, corrosion resistance and ductility. Parts built with EOS Titanium TiCP grade 2 powder can be machined, shot-peened and polished in as-built and heat treated states. Due to the layer-wise building method, the parts have a certain anisotropy.

- Good strength-to-weight ratio

- Good corrosion resistance & ductility

- Parts for medical and other industries

The EOS Quality Triangle

EOS uses an approach that is unique in the AM industry, taking each of the three central technical elements of the production process into account: the system, the material and the process. The data resulting from each combination is assigned a Technology Readiness Level (TRL) which makes the expected performance and production capability of the solution transparent.

EOS incorporates these TRLs into the following two categories:

All of the data stated in this material data sheet is produced according to EOS Quality Management System and international standards

EOS incorporates these TRLs into the following two categories:

- Premium products (TRL 7-9): offer highly validated data, proven capability and reproducible part properties.

- Core products (TRL 3 and 5): enable early customer access to newest technology still under development and are therefore less mature with less data.

All of the data stated in this material data sheet is produced according to EOS Quality Management System and international standards

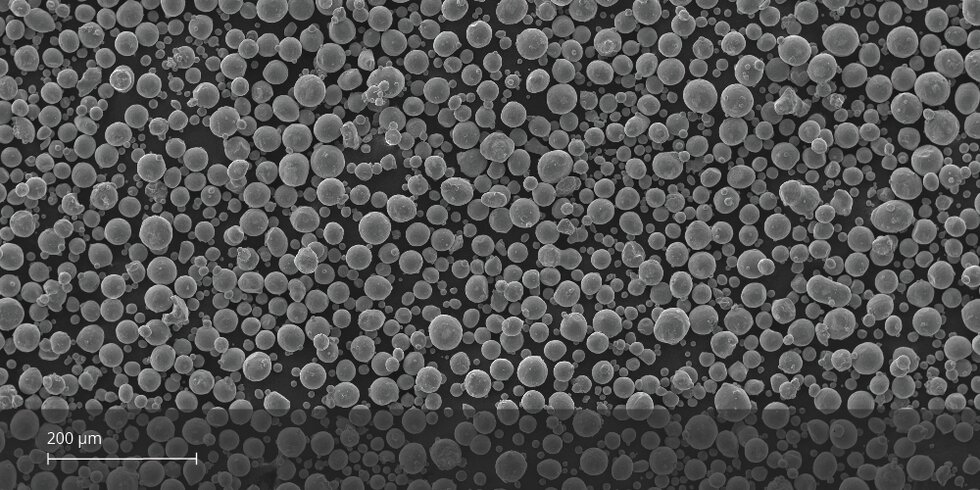

POWDER PROPERTIES

EOS Titanium TiCP Grade 2 powder corresponds to ASTM F67

Powder Chemical Composition (wt.-%)

| Element | Min. | Max. |

|---|---|---|

| N | - | 0.03 |

| C | - | 0.08 |

| H | - | 0.015 |

| Fe | - | 0.3 |

| O | - | 0.25 |

| Ti | Balance | |

Powder Particle Size

| GENERIC PARTICLE SIZE DISTRIBUTION | 38 - 45 μm | |

|---|---|---|

HEAT TREATMENT

Heat treatment procedure

Heat treatment in 700 °C (± 10 °C) for 2 h (± 0.5 h) under argon.