EOS NickelAlloy IN625

Material Data Sheet

EOS NickelAlloy IN625

Parts built from EOS NickelAlloy IN625 have chemical composition corresponding to UNS N06625, AMS 5666F, AMS 5599G, W.Nr 2.4856, DIN NiCr22Mo9Nb. This type of alloy is characterized by having high tensile, creep and rupture strength. Conventionally cast or wrought components in this type of nickel alloy have typically excellent fatigue and thermal-fatigue properties combined with good oxidation resistance. EOS NickelAlloy IN625 is expected to have good corrosion resistance in various corrosive environments. Especially sea-water applications require high pitting and crevice corrosion resistance, stress-corrosion resistance against chloride-ions, high tensile and corrosion-fatigue strength. However, corrosion resistance has not been verified yet and therefore it is recommended to conduct relevant corrosion tests and studies prior to use in specific corrosive environment. Parts built from EOS NickelAlloy IN625 can be heat treated and material properties can be varied within specified range. Parts can be machined, spark-eroded, welded, micro shot-peened, polished and coated in both as-built and in heat-treated conditions. Due to the layerwise building method, the parts have certain anisotropy.

- High tensile, creep and rupture strength

- Heat and corrosion resistant

- Chemical composition corresponding to UNSN06625, AMS 5666F, AMS 5599G

- Racing applications

- Gas turbines in aerospace and energy

- Ship building industry

The EOS Quality Triangle

EOS incorporates these TRLs into the following two categories:

- Premium products (TRL 7-9): offer highly validated data, proven capability and reproducible part properties.

- Core products (TRL 3 and 5): enable early customer access to newest technology still under development and are therefore less mature with less data.

All of the data stated in this material data sheet is produced according to EOS Quality Management System and international standards

POWDER PROPERTIES

EOS NickelAlloy IN625 chemical composition is corresponding to UNS N06625, AMS 5666F, AMS 5599G, W.Nr 2.4856, DIN NiCr22Mo9Nb.

Powder Chemical Composition (wt.-%)

| Element | Min. | Max. |

|---|---|---|

| Cr | 20 | 23 |

| Mo | 8 | 10 |

| Nb | 3.15 | 4.15 |

| Fe | - | 5 |

| Ti | - | 0.4 |

| Al | - | 0.4 |

| Co | - | 1 |

| Si | - | 0.5 |

| Mn | - | 0.5 |

| C | - | 0.1 |

| Ta | - | 0.05 |

| P | - | 0.015 |

| S | - | 0.015 |

| Ni | Balance | |

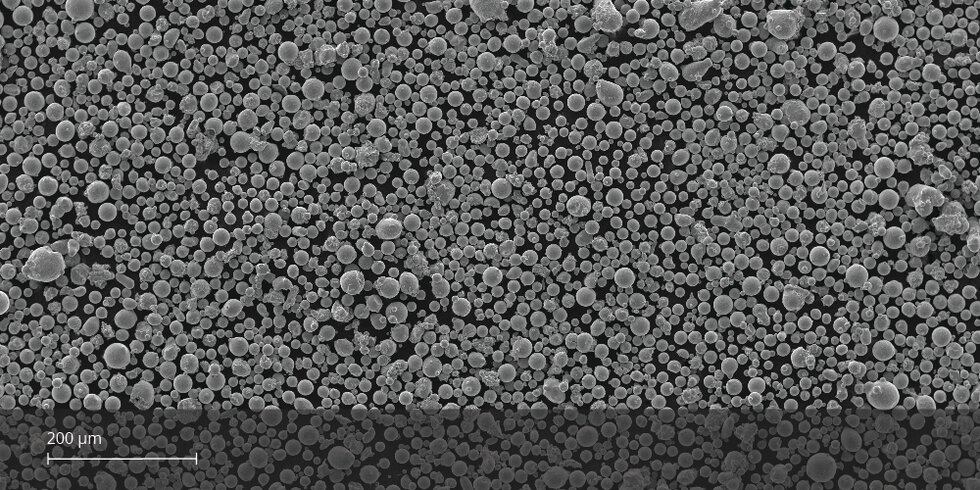

Powder Particle Size

| GENERIC PARTICLE SIZE DISTRIBUTION | 15 - 65 μm | |

|---|---|---|

HEAT TREATMENT

Anneal at 870 °C (1600 °F) for 1 hour, rapid cooling.