EOS CobaltChrome MP1

Material Data Sheet

EOS CobaltChrome MP1

Parts have good corrosion resistance and high mechanical properties even at elevated temperatures plus are nickel-free and show a fine, uniform crystal grain structure. This combination is ideal for many applications in the aerospace and medical industries.

- Corrosion resistance

- Great elevated temperature performance

- Nickel-free

Various applications in aerospace and medical field

The EOS Quality Triangle

EOS incorporates these TRLs into the following two categories:

- Premium products (TRL 7-9): offer highly validated data, proven capability and reproducible part properties.

- Core products (TRL 3 and 5): enable early customer access to newest technology still under development and are therefore less mature with less data.

All of the data stated in this material data sheet is produced according to EOS Quality Management System and international standards

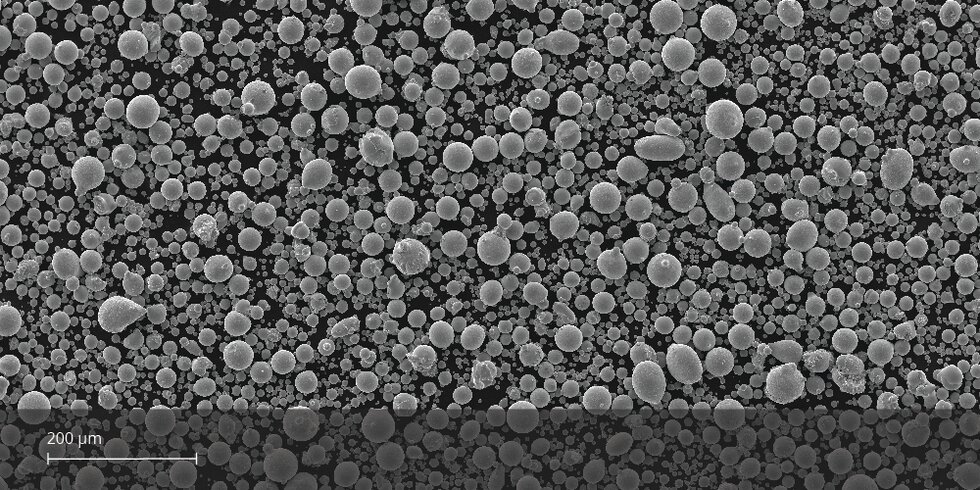

POWDER PROPERTIES

The chemical composition of EOS CobaltChrome MP1 is in accordance with standards ASTM F1537/F799, ASTM F75, ISO 5832-12 and ISO 5832-4.

Powder Chemical Composition (wt.-%)

| Element | Min. | Max. |

|---|---|---|

| Co | Balance | |

| Cr | 27 | 30 |

| Mo | 5 | 7 |

| W | - | 0.2 |

| Ni | - | 0.1 |

| Fe | - | 0.75 |

| Mn | - | 1 |

| Si | - | 1 |

| C | - | 0.14 |

Powder Particle Size

| GENERIC PARTICLE SIZE DISTRIBUTION | 15 - 45 μm | |

|---|---|---|

HEAT TREATMENT

Stress relieving & solution annealing heat treatment relaxes residual stresses, provides anisotropy and increases ductility of the material.

Load parts in the cold furnace with Ar-atmosphere.

Heat up with heating rate of 10°C/min.

Soaking time in temperature of 1150°C ± 15°C (2102°F) for 6h (± 15min).

Quench immediately after soaking to room temperature water.