EOS ToolSteel 1.2709

Material Data Sheet

EOS ToolSteel 1.2709

Ultra High Strength Tool Steel for Demanding Molding Applications

EOS ToolSteel 1.2709 is an ultra high strength tooling grade maraging steel. Its excellent properties are enabled by forming intermetallic phases and precipitates in heat treatment. The properties enable succesful use in diverse applications including injection molding and cold and hot working.

- Ultra high strength and hardness

- Properties adjustable with different heat treatment

- Excellent fatigue strength

- Good machinability

- Plastic injection molding

- Extrusion tools

- Hot pressing tools

- Die casting tools for aluminum and zinc alloys

The EOS Quality Triangle

EOS incorporates these TRLs into the following two categories:

- Premium products (TRL 7-9): offer highly validated data, proven capability and reproducible part properties.

- Core products (TRL 3 and 5): enable early customer access to newest technology still under development and are therefore less mature with less data.

All of the data stated in this material data sheet is produced according to EOS Quality Management System and international standards

POWDER PROPERTIES

The chemical composition of EOS ToolSteel 1.2709 powder is in compliance with EN 1.2709

Powder Chemical Composition (wt.-%)

| Element | Min. | Max. |

|---|---|---|

| Fe | Balance | |

| Ni | 17 | 19 |

| Co | 8.5 | 10 |

| Mo | 4.5 | 5.2 |

| Ti | 0.8 | 1.2 |

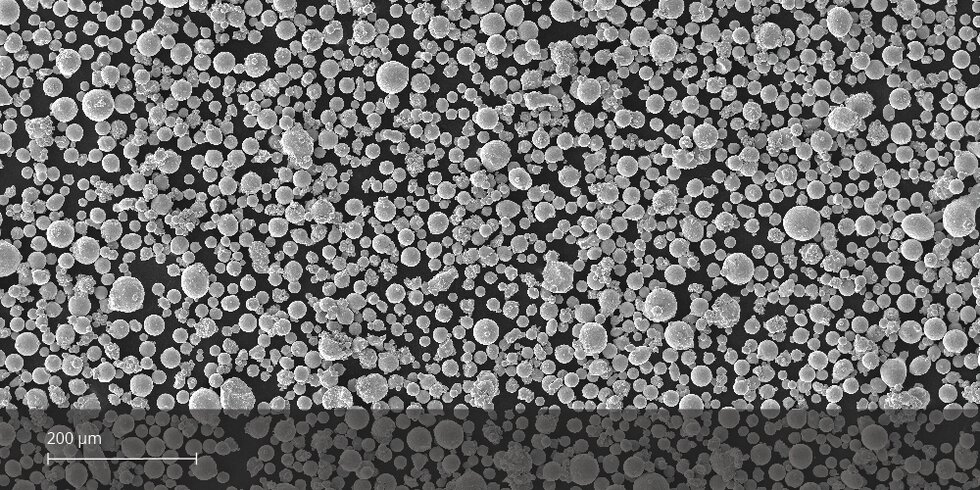

Powder Particle Size

| GENERIC PARTICLE SIZE DISTRIBUTION | 20 - 65 μm | |

|---|---|---|

SEM micrograph of EOS ToolSteel 1.2709 powder

HEAT TREATMENT

EOS ToolSteel 1.2709 can be heat treated to match various needs of different applications. The two step heat treatment can be performed under vacuum or inert gas atmosphere. First step is solution annealing to minimize amount of austenite in the martensitic matrix. The needed hardness and strength is achieved through aging treatment where hardening takes place through forming of intermetallic phases and precipitates.

Solution Annealing:

2 h at 940 °C (±10 °C) measured from the part followed by rapid air cooling to room temperature (below 32 °C). Cooling rate 10-60 °C/min. Reaching room temperature before starting aging treatment is required to achieve desired microstructure.

Aging:

For peak hardness and strength 3-6 h at 510 °C (±10 °C) measured from the part followed by air cooling. Mechanical properties presented in this document achieved through this aging procedure. For bulky parts ensure uniformity of properties by increasing hold time up to 6 h. Also, to maximize fatigue strength, a hold time of 6 h is recommended.