EOS StainlessSteel SuperDuplex

Material Data Sheet

EOS StainlessSteel SuperDuplex

EOS StainlessSteel SuperDuplex is an austenitic-ferritic duplex stainless steel for extreme conditions. The high chromium, molybdenum and nitrogen alloying give excellent corrosion resistance in many difficult environments. The product is optimized for additive manufacturing while maintaining SuperDuplex properties. The optimization of phase balance enables use of the product in as manufactured condition in many use cases. The general pitting resistance equivalent PREN for EOS SuperDuplex is 41 (PREN = %Cr + 3.3 X %Mo + 16 X %N)

- Excellent resistance to uniform, pitting and crevice corrosion

- High strength together with high corrosion resistance

- Oil and gas industry

- Pulp and paper manufacturing devices

- Mining and off-shore equipment

The EOS Quality Triangle

EOS incorporates these TRLs into the following two categories:

- Premium products (TRL 7-9): offer highly validated data, proven capability and reproducible part properties.

- Core products (TRL 3 and 5): enable early customer access to newest technology still under development and are therefore less mature with less data.

All of the data stated in this material data sheet is produced according to EOS Quality Management System and international standards

POWDER PROPERTIES

Powder Chemical Composition (wt.-%)

| Element | Min. | Max. |

|---|---|---|

| Fe | Balance | |

| Cr | 22 | 26 |

| Ni | 9 | 13 |

| Mo | 3 | 6 |

| N | 0.15 | 0.35 |

| C | - | 0.03 |

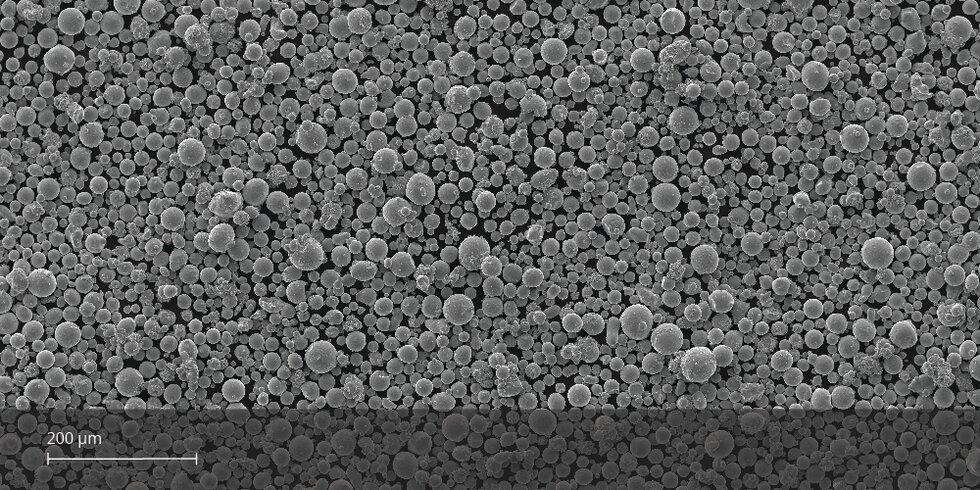

Powder Particle Size

| GENERIC PARTICLE SIZE DISTRIBUTION | 20 - 65 μm | |

|---|---|---|

SEM micrograph of EOS StainlessSteel SuperDuplex powder

HEAT TREATMENT

Heat treatment optional.

Solution annealing:

Hold temperature 1100 °C, hold time 0.5 h when thoroughly heated, water quenching

Typical dimensional change after heat treatment -0.4 % (40 µm) or -0.8 % (80 µm)