EOS NickelAlloy HX

Material Data Sheet

EOS NickelAlloy HX

EOS NickelAlloy HX is a nickel-chromium-iron-molybdenum alloy in fine powder form. Its composition corresponds to UNS N06002.

While the wrought and cast versions of the alloy generally are solution annealed, the laser sintered version has a high strength and good elongation already in the as-built condition. Solution annealing of the laser sintered material will homogenize the microstructure, relax internal stresses and increase the elongation, while slightly decreasing the strength. This type of alloy is characterized by having high strength and oxidation resistance also at elevated temperatures, and is often used up to 1200°C. Therefore its applications can be found in aerospace technology, gas turbine parts, etc. Parts built from EOS NickelAlloy HX can be heat treated and material properties can be varied within specified range. In both as-built and solution heat treated states the parts can be machined, spark-eroded, welded, micro shot-peened, polished, and coated if required. Unexposed powder can be reused.

High strength and oxidation resistance also at elevated temperatures up to 1200°C

- Aerospace

- Gas turbine parts

The EOS Quality Triangle

EOS incorporates these TRLs into the following two categories:

- Premium products (TRL 7-9): offer highly validated data, proven capability and reproducible part properties.

- Core products (TRL 3 and 5): enable early customer access to newest technology still under development and are therefore less mature with less data.

All of the data stated in this material data sheet is produced according to EOS Quality Management System and international standards

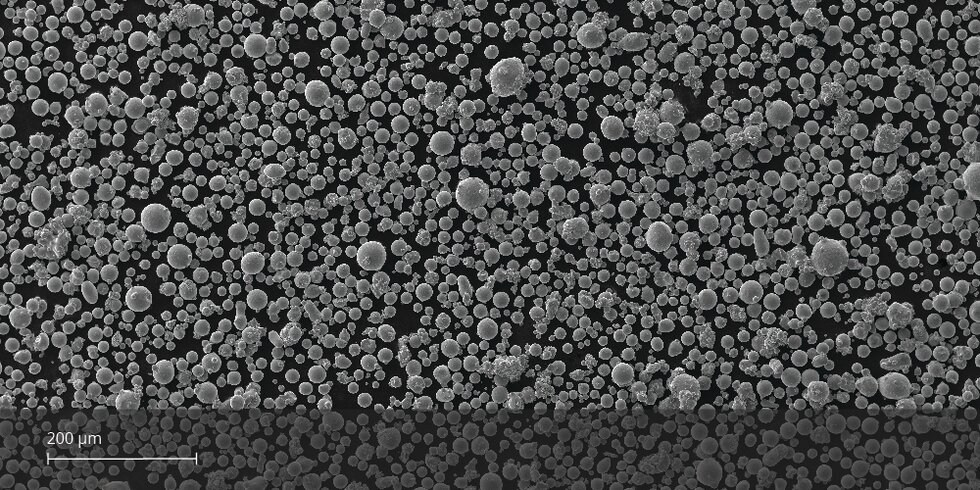

POWDER PROPERTIES

EOS NickelAlloy HX corresponds to UNS N06002.

Powder Chemical Composition (wt.-%)

| Element | Min. | Max. |

|---|---|---|

| Ni | Balance | |

| Cr | 20.5 | 23 |

| Fe | 17 | 20 |

| Mo | 8 | 10 |

| W | 0.2 | 1 |

| Co | 0.5 | 2.4 |

| C | - | 0.1 |

| Si | - | 1 |

| Mn | - | 1 |

| S | - | 0.03 |

| P | - | 0.04 |

| B | - | 0.01 |

| Se | - | 0.005 |

| Cu | - | 0.5 |

| Al | - | 0.5 |

| Ti | - | 0.15 |

Powder Particle Size

| GENERIC PARTICLE SIZE DISTRIBUTION | 15 - 65 μm | |

|---|---|---|

HEAT TREATMENT

Heat treatment procedure according to AMS2773 and AMS5390

Solution anneal at 1177ºC for 1 hour, followed by rapid air cooling to below 60ºC