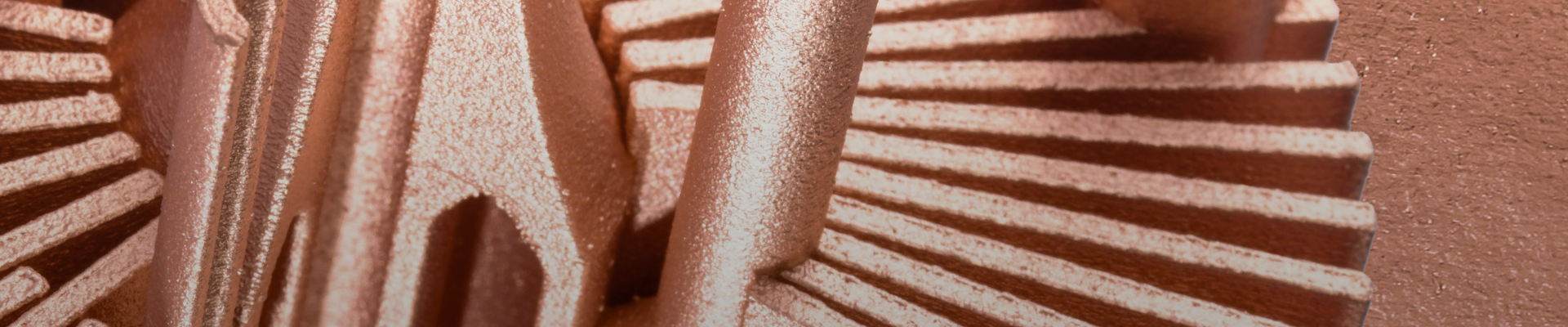

EOS CopperAlloy CuCrZr

Material Data Sheet

EOS CopperAlloy CuCrZr

EOS CopperAlloy CuCrZr has a favorable combination of electrical and thermal conductivity accompanied with good mechanical properties. This alloy reaches its good properties during heat treatment.

- High productivity 12 mm3/s with 80 µm layer thickness

- Moderate to high conductivity in heat treated condition together with good mechanical properties

- Chemical composition corresponds to C18150 and CW106C

- Rocket engine parts

- Heat exchangers

- Induction coils

The EOS Quality Triangle

EOS incorporates these TRLs into the following two categories:

- Premium products (TRL 7-9): offer highly validated data, proven capability and reproducible part properties.

- Core products (TRL 3 and 5): enable early customer access to newest technology still under development and are therefore less mature with less data.

All of the data stated in this material data sheet is produced according to EOS Quality Management System and international standards

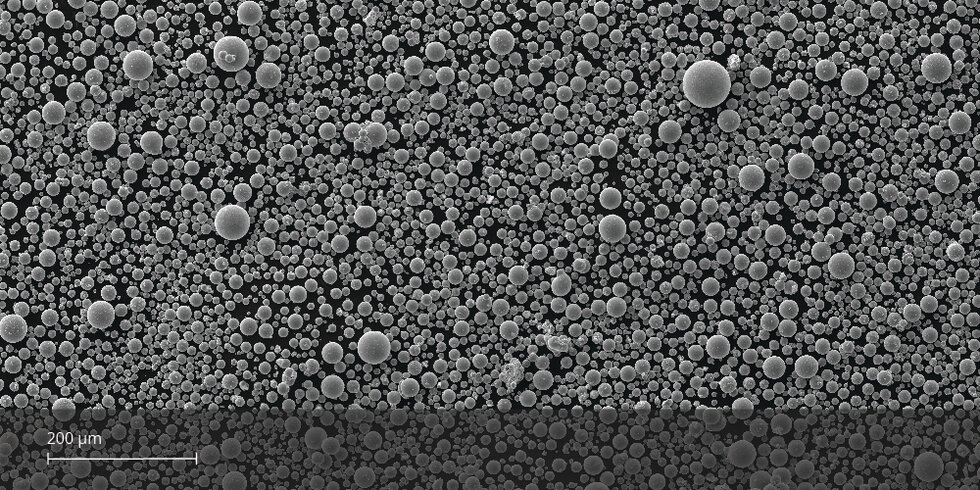

POWDER PROPERTIES

Powder Chemical Composition (wt.-%)

| Element | Min. | Max. |

|---|---|---|

| Cu | Balance | |

| Cr | 0.45 | 1.15 |

| Zr | 0.05 | 0.25 |

| Fe | - | 0.08 |

| Si | - | 0.01 |

Powder Particle Size

| GENERIC PARTICLE SIZE DISTRIBUTION | 15 - 45 μm | |

|---|---|---|

HEAT TREATMENT

CuCrZr can be heat treated to reach different mechanical properties and conductivity values.

Conductivity optimized heat treatement:

Step 1 - Solution: 0,5h hold in 980°C under inert gas flow/atmosphere. Quenching in water straight from the furnace

Step 2 - Ageing: 3h hold in 430°C under inert gas flow/atmosphere. Slow cooling in inert gas until temperature is under 100°C

Tensile optimized heat treatment:

Ageing: 1h hold in 490°C under inert gas flow/atmosphere.

Slow cooling in inert gas until temperature is under 100°C